Vaillant Arotherm Firmware 351.06.07 Problems (Energy Integral)

Back in 1982 my mom and dad got me a Commodore 64 computer.

From the day they bought it for me until the day I sold the machine 5 years later (to fund my Amiga), that Commodore 64 had the very same operating system version.

This was because the operating software code was burnt onto ROM (read only memory) chips. There was no way to upgrade the software without physically replacing the chips on the motherboard.

On old computers, software upgrades only happened very occasionally when a new revision of the board was released.

Fast forward to modern times and computers usually boot their operating system from a hard disk or memory card. Think about the way your Windows, Mac or Raspberry Pi systems run.

By having the operating system stored on writable disk/card you are able to upgrade the software very easily, especially being able to download the updates from the internet.

The third way of a device storing its software or operating system is the machine or device using a writable memory chip. It can be updated, either via the internet (over the air), or sometimes via a code image on a USB stick.

Obviously options 2 and 3 are favourable so that the end device can be updated.

You usually want to update the device for two reasons

- Enhancements or new features

- Bug fixes

So where am I going with this computer history lesson?

Well to put it bluntly, your Vaillant Arotherm Plus heat pump is just like my 40 year old Commodore 64.

The primary software (operating system) running on the outdoor unit is running on a chip that cannot easily be upgraded.

Instead of being able to upgrade the software over the internet like many modern devices, Vaillant recommends replacing the whole circuit board if you want to upgrade the version of the operating system on your Arotherm Plus.

But why do you need to run newer software? What is wrong?

Arotherm Firmware Problem History

January 2021 saw the first comment on a German complaint website about a problem with the “Energy Integral” control mechanism on the Arotherm Plus heat pump.

(Choose translate to English in your browser)

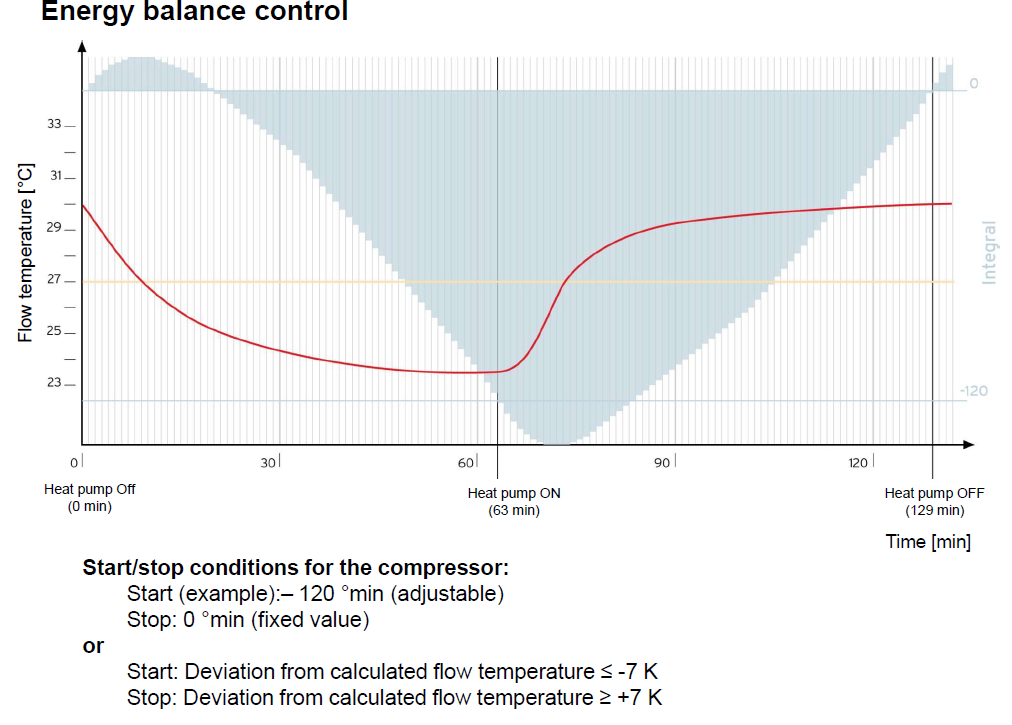

This excerpt from the Arotherm Plus hydraulic station manual gives a good technical summary of what Energy Integral (or Energy Balance) is.

8.8 Energy balance control

The energy balance is the integral from the difference between the flow temperature actual value and target value, which is added up every minute.If the set heat deficit (WE = -60°min in heating mode) is reached, the heat pump starts.

If the supplied heat volume corresponds to the heat deficit (integral = 0°min), the heat pump is switched off.

The energy balancing is used for heating and cooling mode.

You can find a link to that manual here:

In simple terms, Energy Integral is the internal counter the heat pump uses to determine when to turn the heat pump on or off and when cycling is required due to low loads.

The original bug reported on the German website in 2021 suggests there is an issue with how the internal counter is counting up and down.

More on the intricacies of the issue of how it works later.

Vorsprung Durch Technik

The German Vaillant owners community has been way ahead of us in the UK in picking up on this issue as seen in this thread from the haustechnikdialog forum in late 2022.

https://www.haustechnikdialog.de/Forum/t/260734/Vaillant-Arotherm-Problem-Energieintegral-

The folks on that forum determined that the Energy Integral problem presents itself in firmware version 351.06.07 and then was subsequently fixed in 351.09.01

Minor firmware version 351.09.02 followed later, but it is unknown what that added over and above the big fixes in 351.09.01

The haustechnikdialog forum also highlighted that there is a secondary bug in 351.06.07 relating to the “Compr.start heat.from” setting in the installer menu. This bug ignores when you put that setting to -100 °min and it starts at -60 °min regardless.

In Plain English, What is the Problem?

Both these functions (Energy Integral) and (Compr.start heat.from) relate to the process of when the heat pump decides to turn itself on and off during heating and cooling.

By default, the Energy Integral internal counter starts at -60 °min. This is the trigger for the heat pump to start up the compressor to start heating.

The decision flow then goes like this:

- Energy Integral hits -60 °min (heat pump comes on)

- The difference between target flow temp and actual flow temp determines how quickly Energy Integral rises (which increases the counter)

- Energy Integral hits 0 °min (heat pump turns off)

- The difference between target flow temp and actual flow temp determines how quickly Energy Integral falls (which decreases the counter)

- Energy Integral hits -60 °min (heat pump comes on again)

The problem with firmware 351.06.07 is the calculation used in steps 2 and 4 is incorrect as it adds up (and counts down) twice as quickly as it should.

The double counting of the Energy Integral leads to heat pump stopping and starting more times than it should. Cycling more.

This affects efficiency and compressor longevity.

Secondary Bug – “Compr.start heat.from”

There is another setting buried deep in the VWZ AI heat pump interface installer menu called “Compr.start heat.from”, which by default is set at -60 °min.

You can change this setting, which allows you to drop the starting position of the Energy Integral from -60 °min to -100 °min, allowing the installer the option to extend run times even further by starting the calculations at a lower starting point (point 1 in the decision flow referenced above).

But this secondary bug in 351.06.07 means that this -100 °min setting is only acknowledged and used on the very first cycle, but then is ignored and the counting process starts at -60 °min on all subsequent cycles, instead of always using -100 °min.

So you don’t get the even longer cycles that you had hoped for.

This issue is likely to be less common as most people will be on the default value of -60 °min.

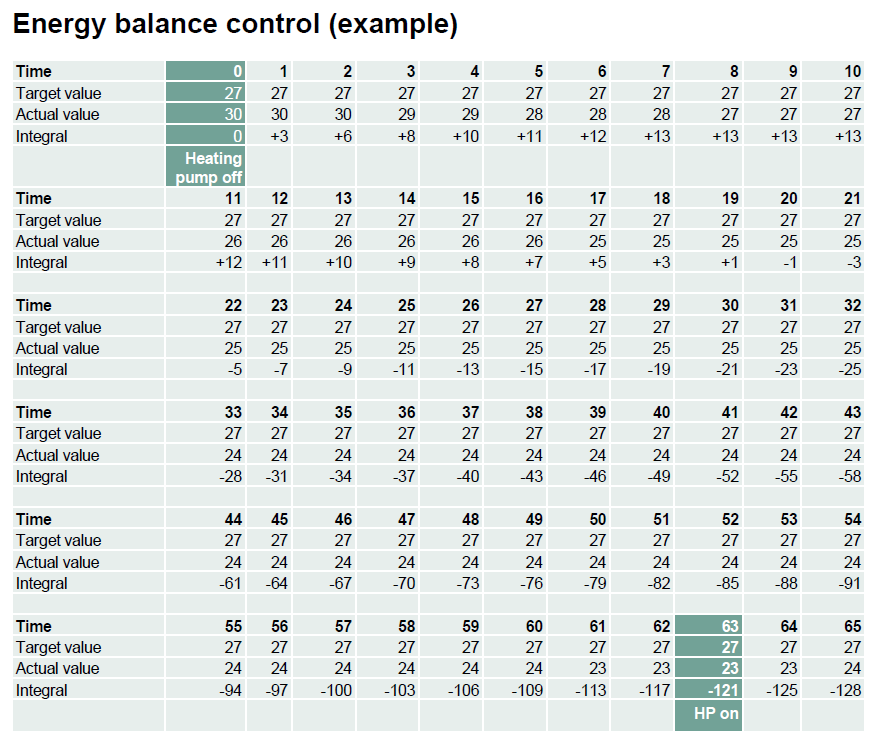

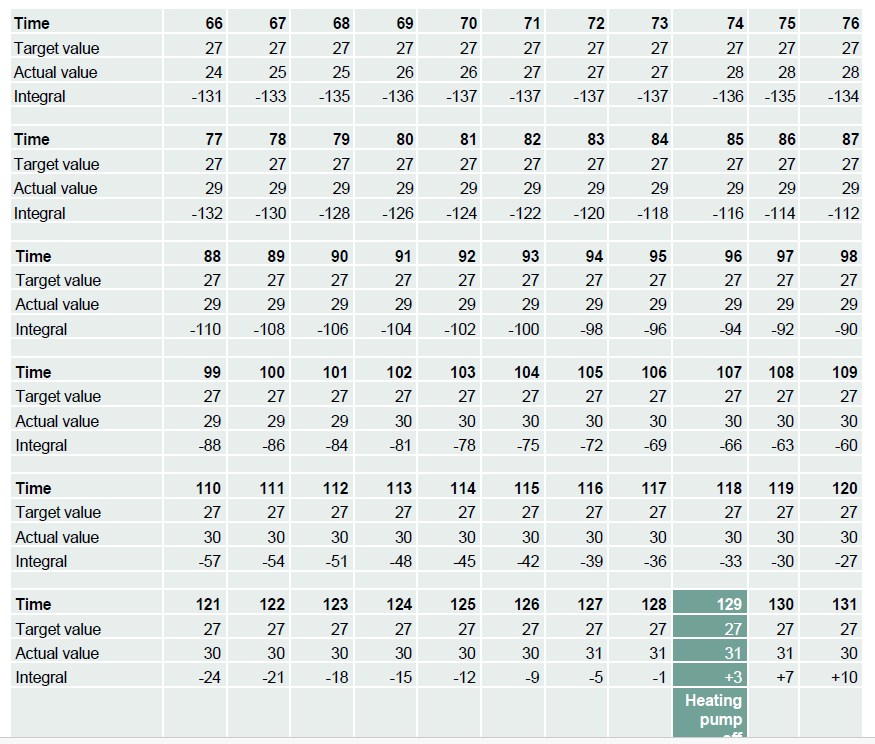

Energy Integral in Pictures

Here is a good graphical explanation of how the “energy integral” works.

This example uses -120 °min though.

Arotherm Plus uses -60°min (or -100 °min with the extra setting)

Link to where diagram can be found:

How Many Cycles Is Too Many?

Your heat pump will start to cycle when the heat requirement of the house is lower than the minimum load of the heat pump.

And this is the time when the firmware bug starts to rear its ugly head.

So in my situation, cycling starts when it is around 7C to 8C outdoors.

But if your heat pump is oversized compared to your heat-loss, you might find cycling starts to occur at lower outside temperatures than this.

If you have a well sized heat pump and have lots of system volume, it might be higher than 7C.

We should all expect to see our heat pumps cycle at some stage when it starts to warm up outside. This is what heat pumps are meant to do.

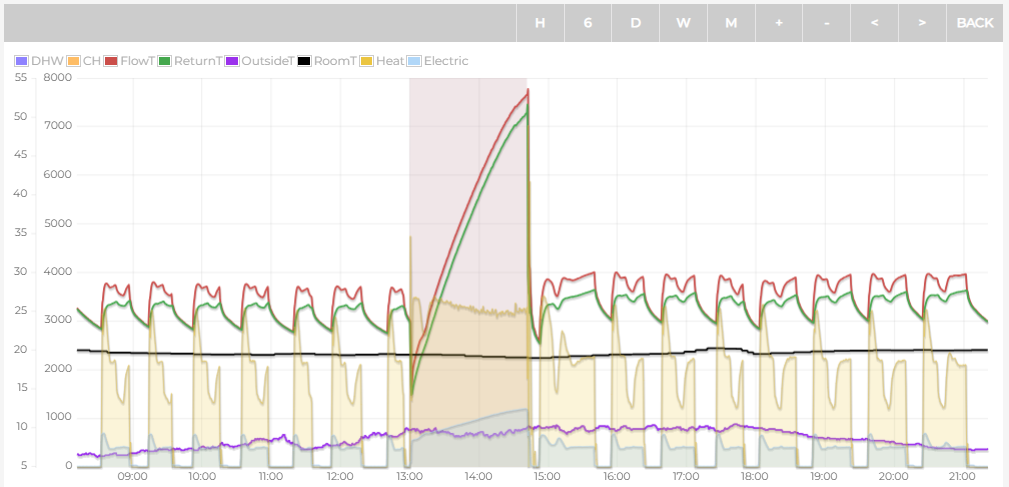

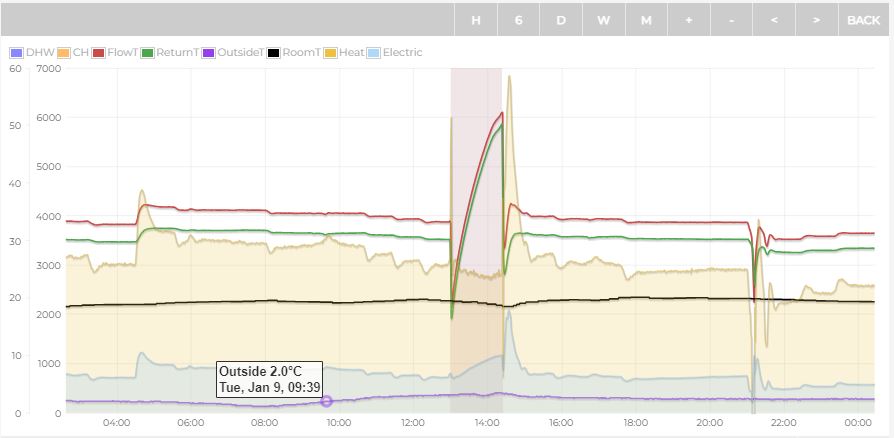

In the graph below, showing a 12 hour period from 23rd April 2024, the outside temperature was between 6.3C and 10.5C.

And even with a 2 hour hot water run in the middle of the graph, there were still 15 on/off periods.

Link to that time period: https://emoncms.org/energystatsuk?mode=power&start=1713856290&end=1713903660

We see 15 cycles here because of the double counting bug. This graph is from my 5kW Arotherm Plus running the troublesome firmware 351.06.07

If the Energy Integral was working correctly I’d hope to see much less cycling in these circumstances.

The vast amount of cycling here is because the Energy Integral internal counter is double counting when it both rises and falls.

On a correctly working system we should expect to see the ‘on’ periods grow to almost double in length instead of what we see here.

And we should also see the ‘off’ periods extend by a further 50% compared to what we are seeing above.

Energy Integral Not Working Properly – Live Video

I have also confirmed the 351.06.07 Energy Integral bug on my VWZ AI Heat Pump Controller live monitor.

At the start of the video you will see

- Target Flow was showing 27.5C

- Current Flow Temp was showing 30C

So as current flow is higher than target, this is a positive 2.5C difference.

The Energy Integral should then rise each minute for each degree C the current flow is above target.

Ie 1 min x 2.5C = Integral should increase by 2.5 in one minute.

At the start of the video the Integral at -58 (16 seconds into the video)

1 minute 24 seconds in the Integral was now -53

And at 1 min 42 seconds it was at -51.

So the Energy Integral was decreasing way quicker than it should.

This is the double counting bug in real life.

- -58 at 16 seconds

- -53 at 1 min 24 seconds

- -51 at 1 min 42 seconds

When it should really have only reached around -55 by the 1 min 30 seconds.

This double-counting results in a shorter “on” period as the integral decreases twice as fast as it should, but also a shorter “off” period. In technical speak, the period is reduced and the frequency increases. The duty cycle however (overall % time on) is the same.

Before and after examples having firmware upgraded

Enough of all the theory, what impact does the difference in the way the energy integral is calculated actually have in practice? Well, the exact impact will depend on the specifics of your installation, but here is one example which clearly shows the impact it has on cycle length.

The two three-hour long snapshots below are from a 7kW Arotherm Plus the day before the firmware was upgraded and the day after it had the circuit board swapped out.

- February 21st 2024 running firmware 351.06.07

- February 21st 2024 running firmware 351.09.02

As you can see, the overnight temperature was the same, around 10C, so everything else was the same. Same weather curve, same target flow temperature etc.

With the updated firmware; the cycle length doubles and the time between cycles also increases due to the now correct Energy Integral calculation. This obviously results in fewer cycles and a small increase in efficiency (COP).

New firmware versus Old firmware differences

- Less cycles (2 versus 3)

- Cycle Length Increases (~55mins versus ~35 mins)

- Off time between cycles increases (30 mins versus 20 mins)

- COP increases (5.02 versus 4.82)

The difference is notable.

The heat pump is ‘designed’ to behave like the latter graph (with new firmware). But for everyone running the older firmware 351.06.07 it behaves like the first graph.

February 21st 2024 (running old 351.06.07 firmware)

Direct link to data in view: https://emoncms.org/app/view?name=MyHeatpump&readkey=206507095efba6cc2493a5f2dc02fa77&mode=power&start=1708477190&end=1708488020

February 22nd 2024 (running newer 251.09.02 firmware)

Direct link to data in view: https://emoncms.org/app/view?name=MyHeatpump&readkey=206507095efba6cc2493a5f2dc02fa77&mode=power&start=1708563550&end=1708574640

Energy Integral Working Properly (351.09.02)

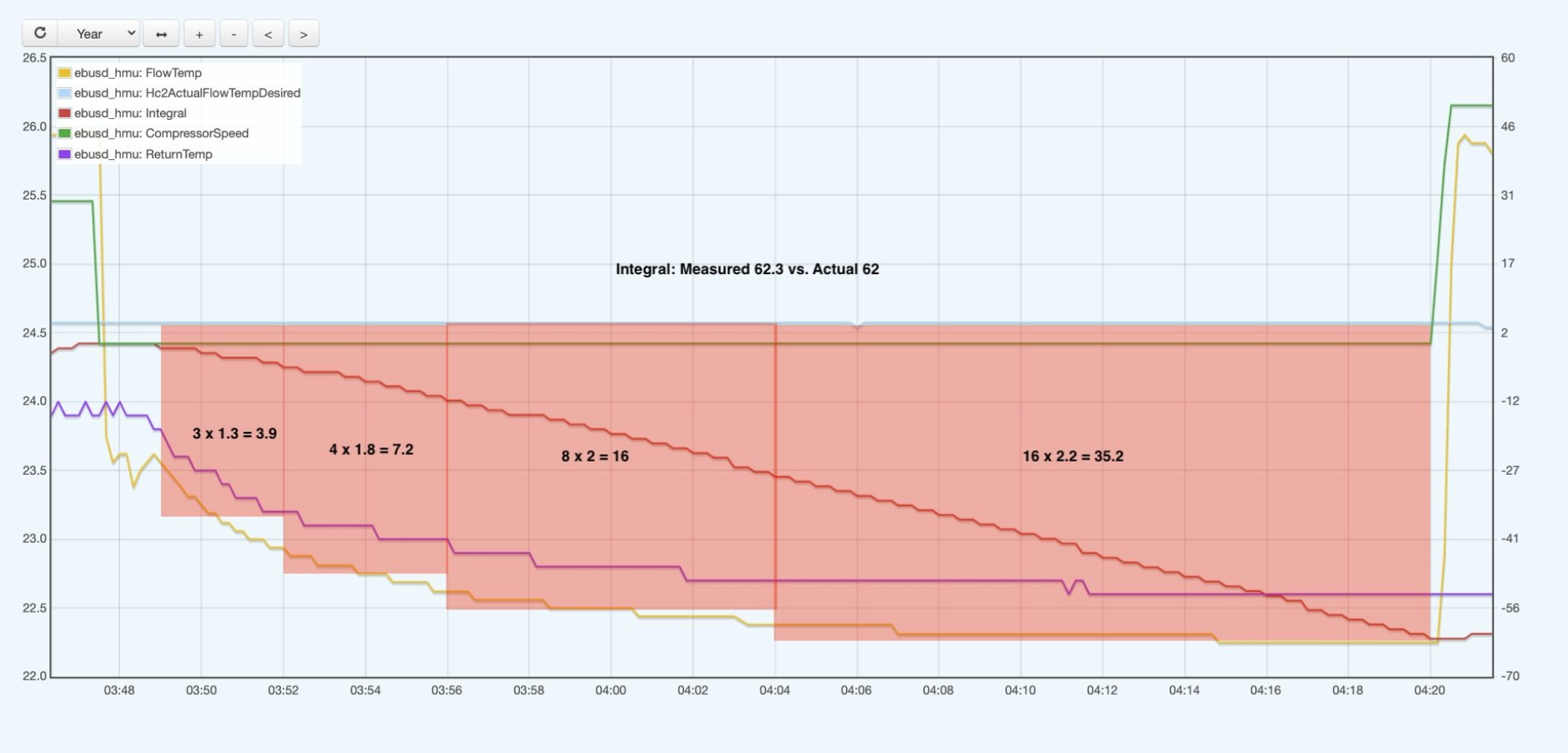

Here is a graph showing Energy Integral on the chart .

On this example we are running the newer firmware, the heating has gone off and there are differences of 1.3, 1.8, 2.0 and 2.2 between the Target Flow Temp (hc2ActualFlowTempDesired – Red) and the actual Flow Temp (Flow Temp – Yellow) across 3, 4, 8 and 16 minutes.

Calculations on the diagram show how the integral now correctly adds up.

How to check what firmware version you are running

From the information we’ve been able to gather, it looks like any sized Arotherm Plus manufactured from the beginning of April 2023 onwards should have the later and bug free 351.09.01 or 351.09.02 firmware.

So if your heat pump was installed prior to April 2023 it’s more than likely got the earlier and problematic 351.06.07 firmware.

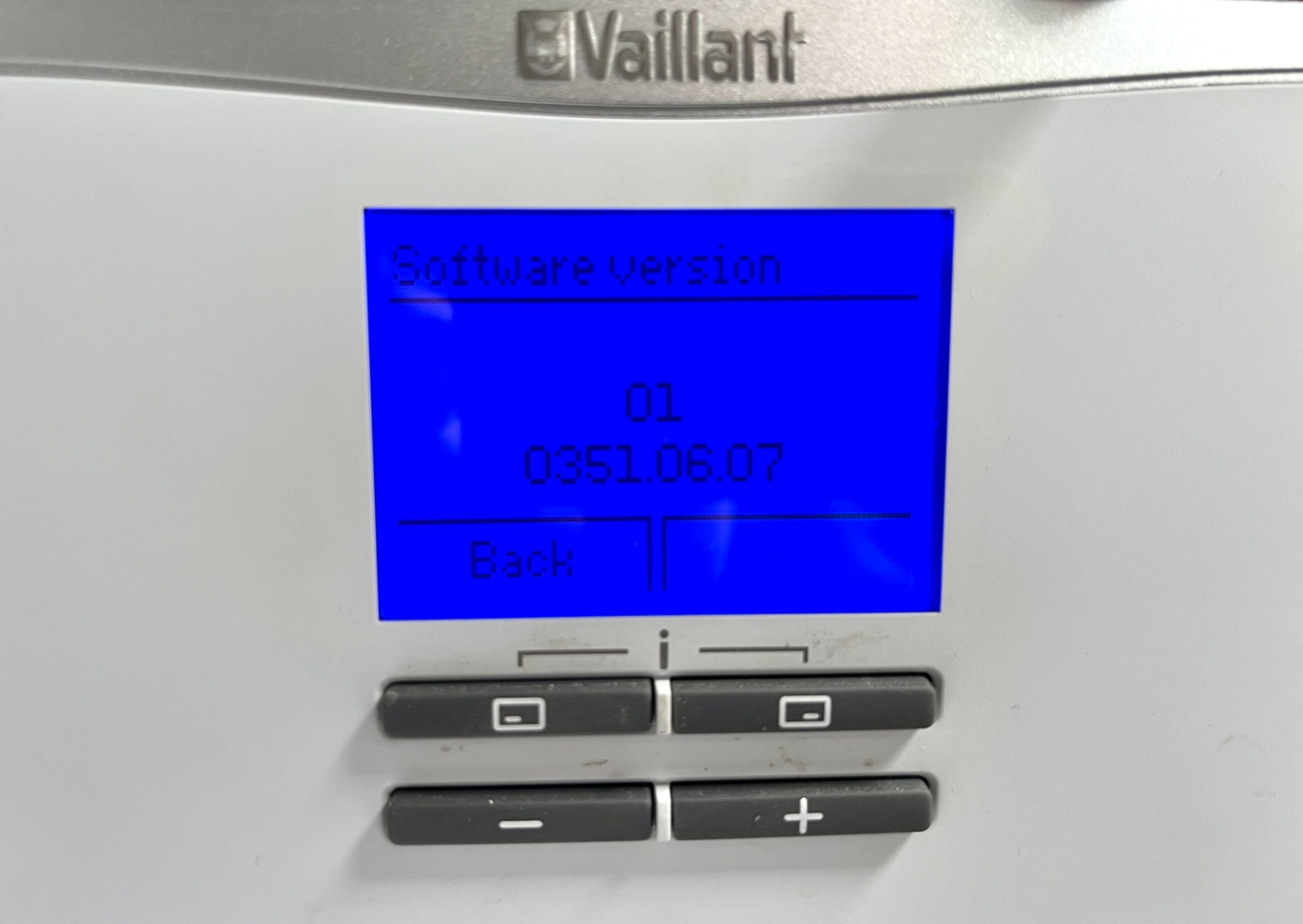

To see exactly what version you are running, head to your VWZ AI heat pump controller.

- Menu

- Installer Level (17)

- Configuration

- Software Version

The software version page shows a series of numbers under multiple headings; 01, 02 and 03.

It is the page showing 01 that starts 0351 is the number that we are interested in.

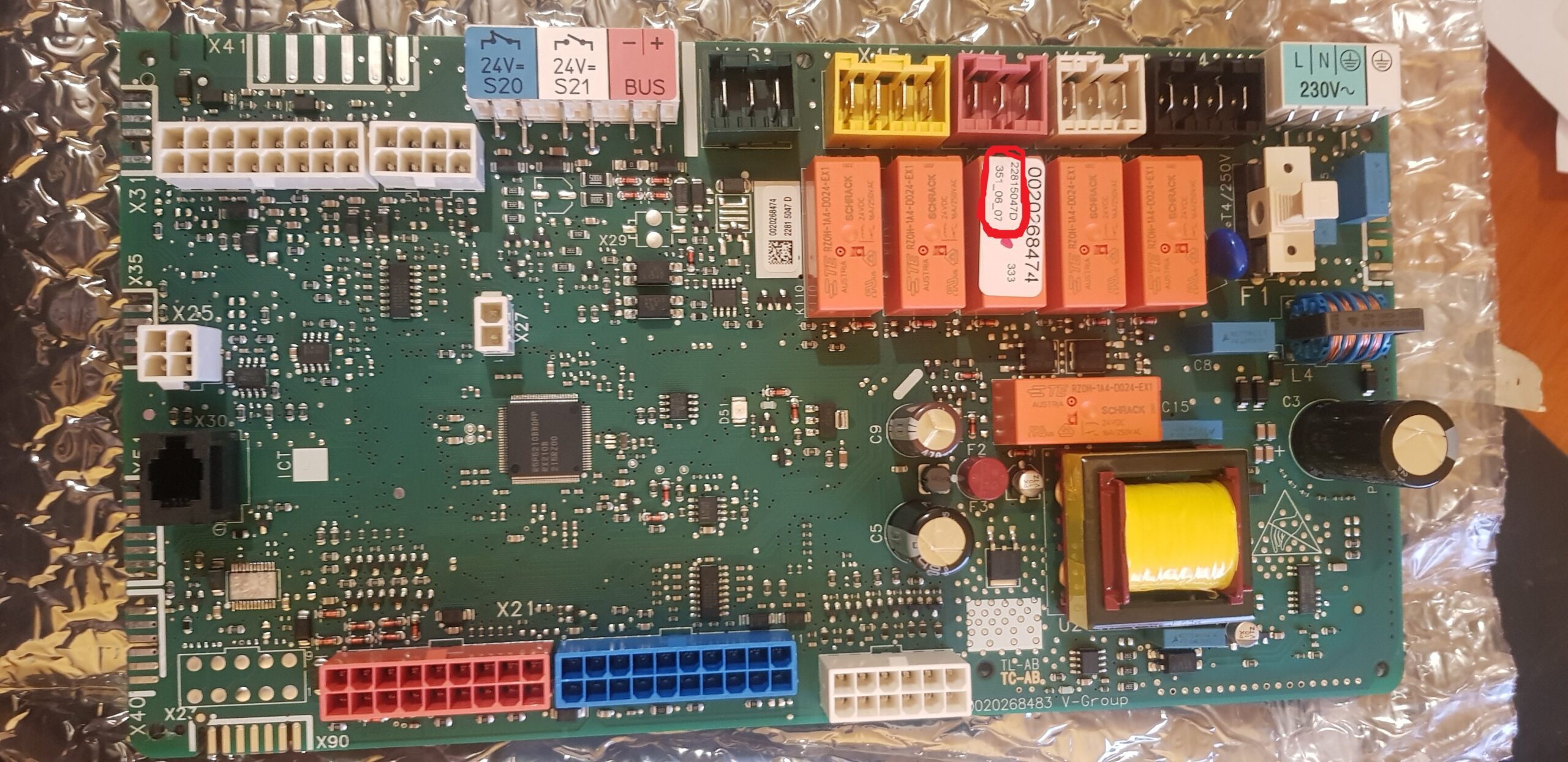

As per the photo below from my system showing that I am running firmware 0351.06.07

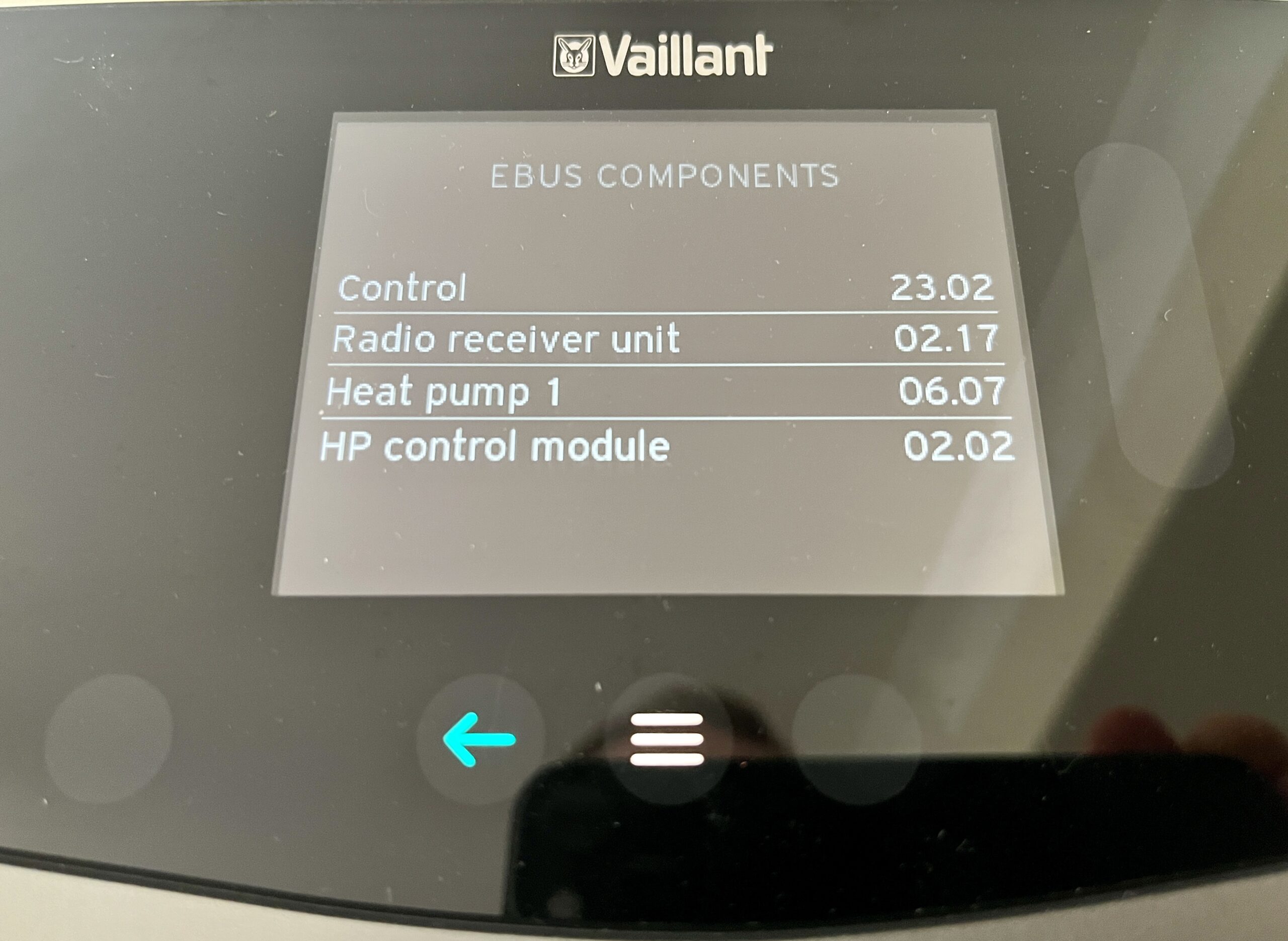

You can also check from the sensoCOMFORT controller.

- Menu

- Settings

- Installer level

- Enter access code (00)

- Installation configuration

- Installation

- eBUS components

Then you’re looking for the numbers next to “Heat Pump 1”.

As you can see on this photo of mine, it says 06.07, indicating firmware 351.06.07

The firmware version is also indicated by a sticker on the chip on the board too (circled in blue).

In the case of this board; firmware 351.06.07

Vaillant Support say software bugs are not faults!

When the circulation pump (or any hardware component) inside your heat pump develops a fault, that is covered under warranty as you would expect.

But when software has bugs that stop the heat pump working as per its own manuals or literature, this is seemingly not covered by warranty.

“Your appliance isn’t currently at fault” was the official reply I received from Vaillant Technical Support after raising this firmware problem as a warranty issue on my 18 month old 5kW Arotherm Plus heat pump.

And this is despite providing all the evidence detailed here.

It does bring up an interesting debate about whether software should be classed the same as hardware when it comes to warranty claims?

I don’t see anything in Vaillant ‘heat pump guarantee’ to suggest software / firmware isn’t covered?

Point 7 from their ‘heat pump guarantee’ seems the closest to covering ‘all major components’.

7.The guarantee will cover all major components of the heat pump against manufacturing defects from the installation date, provided that the heat pump is not beyond economic repair.

https://www.vaillant.co.uk/service/your-guarantee/heat-pump-guarantee/

Should ‘all major components’ include the software/firmware running on their hardware?

My personal opinion is that if Vaillant had made the Arotherm like any other modern device and allowed over the air software updates, none of this would be a problem. They could have just quietly sent the fixes via the internet and no one would have really noticed.

But instead, they made the Arotherm like a 40 year old Commodore 64.

So I think they’ve decided to play the “Your appliance isn’t currently at fault” card to save themselves a wedge of cash as it would require quite a financial outlay to replace each and every faulty circuit board.

The Vaillant part number of the replacement circuit board is 10033771 and as of May 2024 this costs around £215 including VAT.

https://www.theheatxchange.co.uk/sku_VAI0010033771

Vaillant quoted me a fixed priced job of £490 (including VAT) for them to come and swap the board out for me.

I did mention to the support folks that the Energy Integral double counting (and to a lesser extent the “Compr.start heat. From” setting) affects efficiency and more importantly compressor life span.

I argued that I thought it prudent they took a more proactive approach to fixing the issue now, rather than wait to see if compressors failed years down the line, potentially outside of the warranty period.

But as per my comment above, it appears a financial decision has been made to let things play out.

What am I personally going to do?

So I basically I have two choices

- Leave things as they are and run on the old firmware

- Swap the board out at my own cost to get the new firmware

If I leave things as they are, I will just have to live with twice the amount of cycles when it’s 7C+ outside and above. Double the cycles, double the compressor starts and stops. More wear and tear on all the components.

I want the most efficient system I can get. Better efficiency = less money spent on electricity in the long term.

Do I leave it? Or do I get the board swapped out myself?

I am currently 1.5 years into a 7 year warranty. What happens 5 years down the line and my compressor starts playing up because of all the extra hammer it has taken due to the software bug? What will Vaillant’s stance be then?

Vaillant assure me that my warranty remains intact as long as my installer swaps the board out. They just asked that I let them know if I decide to get it swapped out so they could update a note on their system.

I’d just have to buy the board at my own cost and get my installer Damon to do the board swap.

One thing to note on the board swap out. Vaillant did say “you might lose some statistics when you swap the board”. I believe these to be historical usage data held on the board; kW, compressor starts/stops etc. But I’m yet to find out exactly what all those statistics might be.

You would hope that all online data will be okay as this was already uploaded?

I’m not overly bothered though as I use Open Energy Monitor to independently monitor the heat pump anyway. But your usage may vary.

They also said, “On the positive side, the majority of the updates in the firmware are to increase the functionality of the myVaillant connect, so over time you should see extra information on the app (if you’re using it).”

As per the other changes mentioned, I can’t comment on what these positives might be. It would be useful if there were changelogs available for these hardware and software revisions?

Another thing to be aware of: If you do get your board switched out and have one of those really expensive cooling resistors installed, make sure it gets moved over!

Is it worth you doing anything?

If you are already running a newer firmware, 351.09.01 or 351.09.02 you should be fine. Any system cycling on 351.09.01 or 351.09.02 will either be by design (lowest heat pump output) or be the result of some other system design issue.

If you are running the older firmware 351.06.07, then you may want to explore your options.

Your first option is that you could do absolutely nothing and accept Vaillant’s opinion that your heat pump will be fine running the older firmware.

Maybe you don’t see significant or excessive cycling when there is lower heat demand in spring/autumn given that your ASHP is very well-sized or due to the characteristics of your property or system”

However, if you are seeing a lot of cycling (which may be worse due to an oversized heat-pump, or low volume system), or you want to get the very best performance and longevity out of your system, then you would probably benefit more from upgrading to the newer firmware and the extended cycles.

Let’s take a quick look at a couple of the scenarios.

If your system is oversized (the badge size of your Arotherm is larger than your heat loss) then it might be worth considering an upgrade. Talk on the german forums suggest the ‘fixed firmware 351.09.01/02’ helps oversized systems more than it does well sized ones.

The 7kW Arotherm mentioned earlier is slightly oversized and does benefit from the firmware upgrade as we can see in the graphs from the earlier section.

I’m not 100% sure that your system needs to be oversized to benefit though, as mine is pretty well sized (4.2kW measured heat loss at -3C on a 5kW Arotherm heat pump) and I’m still seeing double cycling at 7C upwards. So large chunks of a UK winter.

But my system is low volume, only around 100L, all radiators, no underfloor or buffer/volumiser.

An early reviewer of this document on the other hand, with 200L of underfloor and radiator volume on a well sized 5kW Arotherm running the old firmware isn’t seeing too many issues with short cycles.

So anecdotally we could say that the later fixed firmware may also help systems with lower system volume more than those with larger amounts of active volume.

Note: by system volume we mean the amount of water held within and that flows around the under floor, radiators, buffer tanks / volumisers and all pipework when the system is running. Usually referenced in litres (L). This isn’t anything to do with the size of your water cylinder.

If your system is both low on system volume AND the outside unit is oversized compared to your heat loss then you should consider the firmware upgrade based on what we know so far.

It might be worth heading over to the dedicated Vaillant Arotherm Firmware 351.06.07 Problems thread on the Open Energy Monitor Community to discuss.

Ultimately, all systems will start cycling at some stage. As we’ve seen from the examples above, the newer firmware will be kinder on your compressor (and more efficient) in most circumstances.

But remember, the firmware upgrade cannot solve bad system design problems.

And it cannot solve installers doing a poor job with heat loss surveys and choosing oversized heat pump models.

See my What Size Heat Pump article for lots of info about that.

The later firmware can certainly help with longer run times by fixing the double counting bug and also being able to make use of the -100 °min Compr.start heat.from setting.

But nothing beats good design principles; a correctly sized open loop system with full weather compensation, no zones, no extra pumps, no third party controls, nothing complicated.

Less is more.

What if you don’t have Open Energy Monitor? How can I check my system?

Open energy monitor is an amazing package for monitoring your heat pump. It is a 3 part solution consisting of a heat meter, an electric meter and software.

If you are serious about monitoring your heat pump and would like to get access to all the pretty graphs and data shown in this article, then I’d highly recommend it.

https://shop.openenergymonitor.com/level-3-heat-pump-monitoring-bundle-emonhp/

Once installed you can then get your system included on the https://heatpumpmonitor.org/ platform. Which is an open source initiative to share and compare as much real world heat pump data as possible.

As of May 2024 there are 131 systems listed.

You can see data from every minute/hour of every day from my heat pump going back to November 2022 here: https://emoncms.org/energystatsuk

Having Open Energy Monitor (OEM) makes it very easy to see the amount of cycling your system is doing and at what outside temperature.

This Vaillant firmware bug mainly relates to when the outside temperature rises and your heat pump will start to cycle when the heat requirement of the house is lower than the minimum load of the heat pump.

But there is a way to get a bit of a ballpark view of how your system is doing if you don’t have a system like OEM.

We need to head to your VWZ AI heat pump controller.

- Menu

- Installer Level (17)

- Test Menu

- Statistics

We then need to jot down the readings from

- Compressor Starts

- Compressor Hours

And apply this simple formula

- Compressor Starts / Compressor Hours = average Cycles per hour

In my case

- Compressor Hours: 7194

- Compressor Starts: 9292

- 9292 / 7194 = 1.29 cycles per hour

I’m very curious what my ‘score’ would be with the newer fixed firmware?

In the case of the initial reviewer of this document with the high volume UFH/rads and well sized 5kW system

- Compressor Hours: 4440

- Compressor Starts: 2751

- 2751 / 4440 = 0.62 cycles per hour

So his better sized system and high volume means his system cycles (0.62) less times than mine (1.29).

Sadly, we don’t have the historical statistics from the 7kW Arotherm that had its circuit board replaced as you lose the readings as part of the process. They must be written to the board itself?

But since he had the board replaced:

- Compressor Hours: 379

- Compressor Starts: 316

- 316 / 379 = 0.83 cycles per hour

Ideally, you’d have a whole 365 days or at least a whole winter heating season of data behind these Compressor figures. The figures are cumulative and recorded since installation.

So bear that in mind if you’ve only had your heat pump installed a month and it’s April and it has been 12C outside all month. You’d expect a higher number of cycles during this time compared to the depths of winter when you’d hope for some 24 hours a day running.

For example, my system can run for almost 20 hours straight (excluding hot water and one defrost) when it’s 2C outside.

Direct link to that day: https://emoncms.org/energystatsuk?mode=power&start=1704767820&end=1704846360

So these things average themselves out in the Compressor figures.

Hence a whole winter of data is recommended, where you will get a mixture of longer run times (in close to freezing temperatures) and cycling in higher temperatures.

To wrap this up, let’s try and give some “very rough” guidance from the results of the Compressor Starts / Compressor Hours = average cycles per hour calculation.

- Less than 1 cycle per hour – very good

- Between 1 and 2 cycles per hour – alright, but could be better

- Over 2 cycles per hour – potential cause for concern

Note: this is very experimental early guidance as we are still learning here.

It would be good to see lots of people’s stats over on the OEM forum post so we could update this guidance as time goes on with more real world data and evidence to back it up.

Here is the thread over on the Open Energy Monitor community.

https://community.openenergymonitor.org/t/vaillant-arotherm-firmware-351-06-07-problems-energy-integral/26186

It would be good to come armed with the following information

- Arotherm Model (3.5, 5, 7, 10 or 12)

- Firmware Version

- Pre-Install Heat Loss: kW

- Measured Heat Loss post install: kW

- System Volume: Total litres in UFH, Rads, Pipework, Buffers / Volumisers

- Compressor Hours

- Compressor Starts

- Average cycles per hour (Compressors Starts / Compressors Hours)

- What outside temp your system goes from constant steady state running to cycling

Reminder: This ‘average cycles per hour’ is not a direct correlation to the firmware 351.06.07 bug. It’s just a summary of how much cycling your heat pump has been doing. But your average ‘could’ have been affected by the bug as we’ve seen by various example systems in the article.

Big Thank You and Shout Outs

A massive thank you has to go to @FinchampsteadPH on Twitter / X for helping jointly write this article. I could not have done this without him.

https://twitter.com/FinchampsteadPH

He was lucky enough to raise a warranty call with Vaillant before I did and had his board swapped out for free under warranty.

So we have been able to get some before and after technical details of the issues.

Also big shout outs to the folks on the Open Energy Monitor forums, specifically the Arotherm Owners Thread.

https://community.openenergymonitor.org/t/vaillant-arotherm-owners-thread

Finally, Open Energy Monitor and their amazing Heatpumpmonitor.org platform.

We would have never been able to track down this issue without the heat pump monitoring platform.

Referral information and free credit offer

If you find the content of this website useful and are thinking of joining Octopus Energy, please consider using my referral code or ‘buy me a coffee’ to help support running costs of the website.

Using this referral code will gift you £50 of free Octopus Energy credit after signup: https://share.octopus.energy/linen-pearl-869

If you would like to ‘buy me a coffee’ to show support, please use this link: http://buymeacoffee.com/SVHgIbUYM

If you’re considering owning part of a wind farm through Ripple Energy, get £25 of free credit (if investing more than £1000) using my Ripple referral link.

Energy Stats can also be found on Twitter / X. Please follow us @energystatsuk for daily Agile tariff pricing graphs and summaries.

We have also started posting the same graphs over on Mastodon. You can find us here: https://mastodonapp.uk/@energystatsuk

And we are even trying to get the info out via Instagram. Find us here: https://www.instagram.com/energystatsuk/

Note: The current and past performance of energy pricing is not necessarily a guide to the future.